Concrete Pipe Seals

Concrete pipe seals are essential components used in the construction and maintenance of concrete pipes. These seals play a vital role in ensuring the integrity, functionality, and longevity of concrete pipes, which are commonly used for drainage, sewage, stormwater management, and various underground infrastructure applications. Below, you'll find an in-depth exploration of concrete pipe seals, their types, functions, and significance.

**Types of Concrete Pipe Seals:**

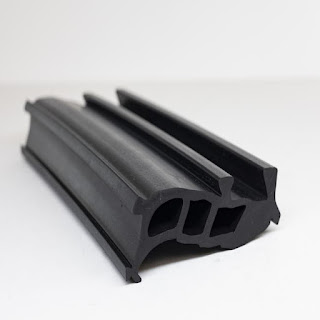

1. **Rubber Gaskets:** Rubber gaskets are one of the most common types of seals used in concrete pipes. These gaskets, typically made from EPDM (Ethylene Propylene Diene Monomer) rubber or neoprene, create a watertight and airtight seal between concrete pipe joints. They are available in various profiles and shapes to accommodate different pipe sizes and configurations.

2. **Mastic Seals:** Mastic seals, also known as mastic asphalt seals, consist of a sticky, viscous compound applied to the joint surfaces of concrete pipes. When two pipes are joined, the mastic seal fills gaps and irregularities in the joint, providing an effective barrier against water infiltration and soil intrusion.

3. **Compression Seals:** Compression seals are designed to be compressed between the spigot (male end) and the bell (female end) of concrete pipes during installation. These seals create a secure and watertight connection while accommodating slight movement and settlement of the pipes.

4. **O-Ring Seals:** O-ring seals are circular rubber seals with a cross-sectional shape resembling the letter "O." They are placed in a groove or recess within the pipe joint. When the pipes are connected, the O-ring compresses to form a reliable seal, preventing water or sewage leakage.

**Functions and Significance:**

1. **Watertight Seal:** The primary function of concrete pipe seals is to create a watertight barrier between the joints of concrete pipes. This prevents the infiltration of groundwater, soil, or contaminants into the pipe, ensuring efficient drainage or sewage conveyance.

2. **Airtight Seal:** In certain applications, such as sanitary sewer systems, an airtight seal is crucial to prevent the release of noxious gases or odors from the pipe system into the environment. Concrete pipe seals provide this airtight barrier.

3. **Structural Integrity:** Properly installed seals contribute to the structural integrity of the pipe system. They help distribute external loads, resist soil or hydrostatic pressures, and prevent joint separation or failure.

4. **Prevention of Erosion:** By sealing the joints, concrete pipe seals prevent erosion or undermining of the surrounding soil, which can lead to sinkholes or instability in the pipeline.

5. **Longevity:** Concrete pipe seals extend the service life of the pipes by minimizing the risk of leaks, corrosion, and deterioration. This reduces maintenance and replacement costs over time.

6. **Versatility:** Concrete pipe seals are suitable for various types of concrete pipes, including reinforced concrete pipes (RCP), precast concrete pipes, and concrete culverts, making them versatile and widely applicable.

7. **Ease of Installation:** Many concrete pipe seals are designed for ease of installation. This reduces labor costs and ensures that the seals are correctly positioned to provide effective sealing.

8. **Environmental Protection:** Properly sealed concrete pipes help protect the environment by preventing the discharge of pollutants, sewage, or contaminants into natural water bodies or the surrounding soil.

In conclusion, concrete pipe seals are indispensable components in the construction and maintenance of concrete pipe systems. Their ability to create reliable watertight and airtight seals is essential for efficient drainage, sewage conveyance, and environmental protection. These seals contribute to the long-term performance and safety of underground infrastructure, making them a crucial consideration in civil engineering and municipal projects.

Yorumlar

Yorum Gönder